Spindle control panel

Spindle control panel

• On / off buttons for the spindle • Speed potentiometer • Emergency brake • Supplied for 24V

Fixing system

Fixing system

• For the rotation axe - enabling easy changing of the working instruments

Lift module

Lift module

Lift module for changing the position of the working table • Remote control panel with buttons for lifting up and down the level of the machine • The console allows you to save three different levels with the option to automatically change the positions • Lifting up modules with movement up to 410 mm

impeller and

peristaltic pump

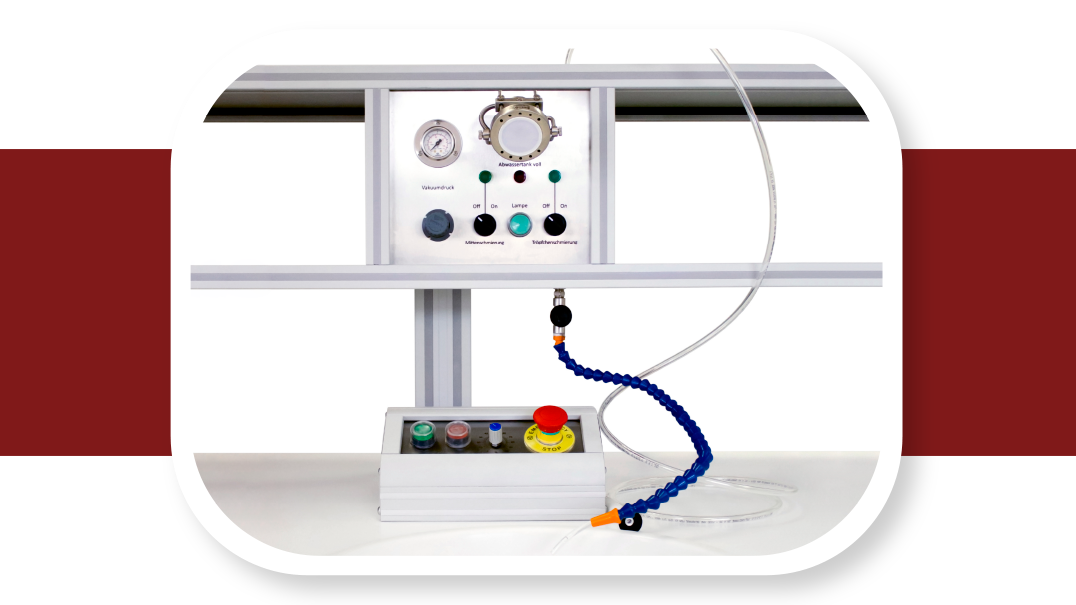

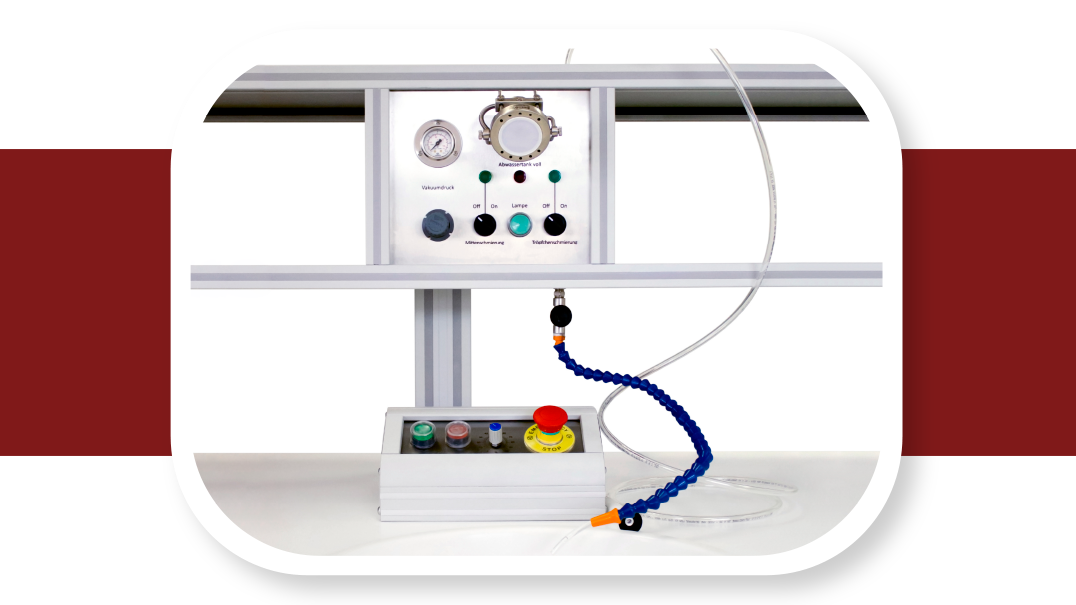

Control panel for vacuum and cooling lubrication

Control panel for vacuum and cooling lubrication

• Manometer • Pressure regulator • On/off button for starting the cooling water liquid to flow from the top of the tool with green indicator • On/off button for start the cooling water liquid to flow through the working tool with green indicator • LED lamp with on/off button • Red light indicator for full level alarm of the waste liquid

Cooling by drip lubrication with electromagnetic valve • Option 1

Cooling by drip lubrication with electromagnetic valve • Option 1

The cooling water liquid may flow from the top of the tool • Button on/off to distribute the water to the working basin • Green indicator sensor – for working of Droplet lubrication • Throttle to regulate the water level Cooling by drip lubrication with electromagnetic valve. The operator can control where the water runs.

Cooling by drip lubrication with electromagnetic valve • Option 2

Cooling by drip lubrication with electromagnetic valve • Option 2

The cooling water liquid may flow through the working tool • Button on/off for water distribution through the working tool • Green indicator sensor – for working of Droplet lubrication • Throttle to regulate the water level

Cooling by drip lubrication with electromagnetic valve

Cooling by drip lubrication with electromagnetic valve

• Possibility for connecting to central water supply

There are two options for the waste liquid • Option 1

There are two options for the waste liquid • Option 1

• Collection tank for waste water with automatic full level alarm. There is a red light indicator on the remote control table. The sensor turns off the machine when the drainage water in the waste container reaches a maximum level.

There are two options for the waste liquid • Option 2

There are two options for the waste liquid • Option 2

• Possibility of connecting the machine direct to a bigger settling system